Biopharmaceutical researchers look to surface plasmon resonance to expedite kinetic studies, making mAb development more cost-effective.

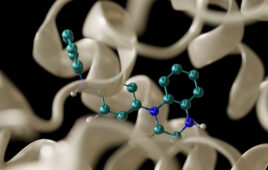

Antibodies and antibody fragments have long been essential tools for biological research, and are now rapidly gaining importance as therapeutic agents. Surface plasmon resonance (SPR)—label-free, biosensor-based systems—have been widely used to study bimolecular interactions in real time, and have come to be regarded as a gold standard for antibody characterization. By providing high-quality kinetic and affinity data, rapid active concentration determination, and the unique ability to detect low-affinity, antibody-antigen interactions, SPR technology-based systems can be used throughout the entire antibody development process, from early screening of antibody-producing cell clones through to clinical immunogenicity studies, as well as final product release testing. GxP (GLP, GCP, GMP)-compliant software and comprehensive validation support enable appropriate systems to be used in regulated quality control applications.

Early development

Monoclonal antibodies (mAbs) are a powerful class of reagents, but their development is a costly and time-consuming process. A critical bottleneck in early development of mAbs is the screening of hybridoma cell clones, which must be maintained in large numbers until the best candidate mAbs are confidently identified. SPR systems are used to screen mAb-antigen binding characteristics directly from crude cell supernatants, providing rapid, real-time monitoring of the whole binding interaction and crucial kinetic information on which to base selection decisions.

|

In collaboration with Amgen, Thousand Oaks, Calif., and Dr. David Myszka of the University of Utah, the Biacore A100 SPR-based instrument was used to rapidly screen 384 crude hybridoma samples expressing human mAbs. Taking binding responses during both the association and dissociation phases enabled 16 mAbs with the required binding properties to be selected for detailed kinetic characterization. As shown in Figure 1, the high-resolution analysis enables mAbs with almost identical affinities to be clearly distinguished by their quite different kinetic characteristics. Kinetic properties (such as slow off-rates) are often of crucial importance for the intended therapeutic application. This information enables more efficient, confident selection of mAbs earlier in the development process.1

Label-free screening assays with SPR technology support the process of selecting candidates with better efficacy, and increase the probability of success in preclinical studies and clinical trials.

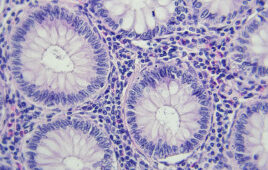

Immunogenicity, safety, and efficacy

The safety and efficacy of protein-based therapeutics, such as mAbs, can be greatly influenced by their immunogenicity. Even humanized antibodies inevitably induce an immune response in patients. This may, at best, reduce the efficacy of treatment and, at worst, lead to the development of life-threatening adverse reactions. Measuring the antibody response to treatment is the responsibility of the pharmaceutical and biotechnology industry. Novel, protein-based therapeutics also require post-marketing surveillance, where immunogenicity testing is a US Food and Drug Administration (FDA) requirement. Both the industry and regulators are looking for more informative assays to monitor immunogenicity. SPR technology-based immunoassays have moved to the forefront as a promising technology, offering several advantages in the rapid detection and subsequent characterization of clinically-relevant antibodies in patient serum samples generated as a response to therapeutic proteins (Figure 2). This provides a high level of information and content analysis, with response level monitoring, isotype and subclass determination, and concentration estimates provided by one instrument. The real-time detection also allows kinetic behavior to be observed, enabling the maturation of immune responses over time to be monitored. Moreover, recent results have shown that detection by a SPR system is the optimal way to reliably detect low-affinity antibodies that may be clinically significant, but which are likely to be missed using other techniques.2,3

SPR technology-based immunoassays support safety assessment in the preclinical and clinical development process by providing the investigator and sponsor with reliable information about the immunogenicity of protein-based therapeutics.

|

Process development and QC

The development of therapeutic antibodies involves several stages, including immunogenicity studies, in-process control, and product release testing that are under strict control by regulatory authorities including the FDA.

During in-process and quality control, validated assays must be able to monitor the biological product through multiple stages of expression and purification. The real-time analysis provided by SPR systems can enable rapid, reliable quality control monitoring with minimal assay development time. Real-time detection also can be implemented for process analytical technology (PAT). Figure 3 demonstrates how using Biacore SPR technology in place of a standard enzyme-linked immunosorbent assay (ELISA) reduced assay times from seven hours to two hours, saving 15 hours in the first three purification steps alone, and reducing manpower by more than 50%.

Other studies have shown that using a Biacore assay in place of a standard ELISA often reduces assay times and improves assay reproducibility, with significantly lower percent coefficient of variation values.4 In addition, the ability to incorporate active concentration, affinity, and kinetic assays also significantly improves the quality of the product characterization. As shown in Figure 4, SPR technology-based assays can provide better precision and reproducibility than alternative technologies.

| Figure 3: In-process control using Biacore technology versus ELISA. Concentration determination in downstream protein purification process. (Source: Boehringer-Ingelheim Pharma KG) |

||

|

Process step |

Mouse -IgG ELISA |

Biacore |

|

Harvest pool |

7h |

2h |

|

30 kD Diafiltration |

7h |

2h |

|

IEX Chromatography |

7h |

2h |

|

Total time |

21h |

6h |

The incorporation of kinetic analysis in QC monitoring can provide detailed binding data that is highly relevant for clinical function of the biological product. Various biopharmaceutical companies have demonstrated the usefulness of this approach. Differences in kinetic behavior (faster or slower on/off-rates) can rapidly identify suspect batches of therapeutic proteins. For example, the kinetic QC data is sometimes crucial in the early termination of cell clones used for producing active substance batches.

SPR-based systems can make a similar contribution in release testing of final product. The FDA has approved such a binding assay/drug product release test (Amevive from Biogen Idec Inc.) for recombinant protein therapeutics.5

|

Other key applications for label-free, direct-binding SPR technology-based assays are assessment of manufacturing changes and stability studies and formulation. For example, kinetics can be used to evaluate the effect of manufacturing changes on drug product binding properties before and after scale up of purification processes, or to address the effect of technology transfer on product when outsourcing to contract manufacturers and partners. SPR technology can also play an important role in a number of key areas to establish comparability for developers of biogenerics. This includes immunogenicity, which is a key aspect of evaluating product comparability.6

Summary

SPR technology-based systems are making a contribution to the development of antibodies, particularly in biotherapeutics. Providing higher quality, and, in some instances, unique data compared to alternative methods such as ELISA, SPR analysis reduces cost and improves safety and efficacy during antibody development. Designed for use in GxP environments, these systems are also in use in upstream and downstream operations and QC applications, where their value is increasingly recognized by major pharmaceutical companies and regulatory authorities. SPR technology therefore offers a powerful solution that spans the entire process of antibody development and production. Using SPR technology throughout the entire development process significantly increases the probability of success of selected antibody drug candidates and accelerates the time-to-market.

References

1. Biacore Application Note 84: https://www.biacore.com/lifesciences/technology/application_notes/index.html

2. Mason, S. et al. Curr. Med. Res. Opin. 19:651-659,2003.

3. Swanson, S. et al. Nephron Clin. Pract. 96:88-95, 2004.

4. Biacore Application Note 38: https://www.biacore.com/lifesciences/technology/application_notes/index.html

5. Reynhardt, K.O. et al.: Int. J. Biochromatography. 6:255-267, 2001.

6. Sundberg, F et al. Pharmaceutical issues in perspective, Scrip mag. Oct. 2005, 39-41.

About the Author

Fredrik Sundberg is Director Strategic Market Development, GE Healthcare, where he advises on R&D projects and has specialist knowledge in the areas of regulatory compliance and validation support, and frequently provides GxP (GLP, GCP, GMP) training to the industry.

This article was published in Drug Discovery & Development magazine: Vol. 12, No. 2, February, 2009, pp. 22-24.

Filed Under: Genomics/Proteomics