Ireland is a country perhaps best known for pints of the black stuff and rugged emerald vistas and James Joyce’s evergreen “Ulysses.” In medical circles, it also has a reputation as a pharmaceutical hub. With a population of just 4.5 million, Ireland is punching far above its weight in this industry. Nine out of the 10 largest pharmaceutical companies in the world have plants here, making Eire the seventh largest exporter of medicines.

Now Ireland is set to toast another important milestone and become a leader in the development of the most cutting-edge drugs: biopharmaceuticals. Made from strings of complex proteins, biopharmaceuticals — or biologics for short — are the fastest-growing class of drugs. They range from synthetic insulin to medicines that are being used to treat diseases such as cancer and rheumatoid arthritis.

In Cork — where Pfizer, Boston Scientific and GlaxoSmithKline already have factories — GE is preparing to build a biopharma campus that will consist of four manufacturing facilities tailored to the complex processes involving the creation of biologics. The campus will be managed by GE. The facilities will belong to independent biopharma companies, with GE running centralized shared utilities and site services.

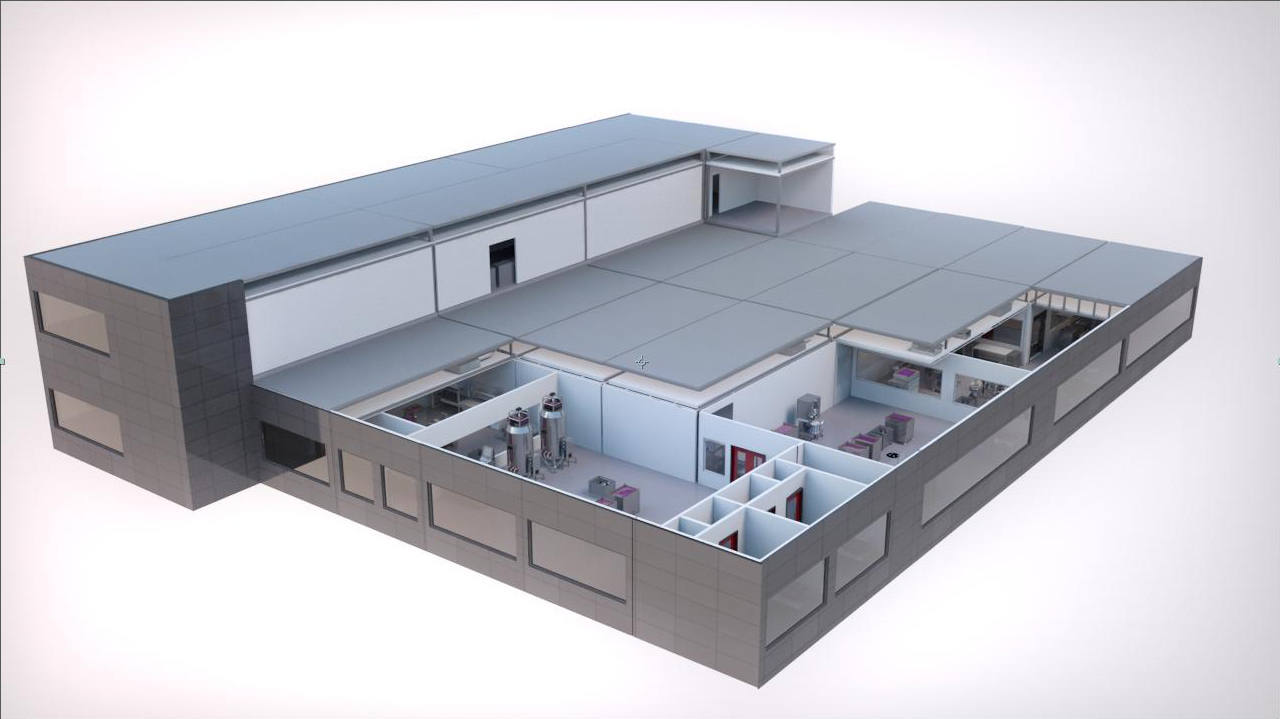

Construction is set to begin next year, and the campus will be up and running a year later. The builders can move fast thanks to GE’s KUBio — a LEGO-like, prefabricated design for biologics plants that can be quickly assembled and tailored to fit the needs of specific producers. GE recently opened the first KUBio factory in China, and more are under construction. The company is investing $170 million in the Irish project, which is also expected to create 500 new jobs.

Above: GE’s KUBio modular factory for biologics. Image credit: GE Healthcare Life Sciences. Top Image: National Convention Centre and Samuel Beckett Bridge on River Liffey, Dublin. Image credit: Getty Images

GE engineers designed KUBio for the breathtakingly complex biologics manufacturing methods. Take acetaminophen, the active ingredient in common pain-relief tablets. The way to make it is pretty straightforward: chemical synthesis. But the active ingredients in many biologics must be grown from artificially formed DNA strands made inside living cells. The cells are much more sensitive to the tiniest changes in temperature and minute contamination. As a result, making biologics requires hundreds of process controls to ensure that systems are consistent.

The new plants will include equipment such as large, 2,000-liter bioreactors. Workers will use them to grow cells and produce protein strains that can be purified and turned into drugs. “Annual product capacities range from tens of kilograms, to 400 kilograms of a protein that’s then shipped offsite within a manufacturer’s own site network,” says GE’s David Radspinner, who is overseeing the development of the massive, 37-acre BioPark in Cork.

GE is not getting into the drug-development business, but it provides the infrastructure for biopharma companies. The idea behind GE’s BioPark in Cork is to help customers get complex biological drugs to market faster at a time when recent research shows a capacity crunch. Drug companies both large and medium-sized will be able to bid for space in the four, fully outfitted factories, Radspinner says

Buyers of each factory are expected to stay put for several years as owners and operators. For a large pharma, a factory on the campus could provide some much-needed manufacturing flexibility. For a medium-sized firm, it offers a chance to enter the growing drug manufacturing industry in Ireland.

Companies on the site will share services, warehouses and the sterile liquids that are needed to run some of the manufacturing processes. GE will also collaborate with the National Institute for Bioprocessing Research and Training (NIBRT) in Dublin to create a Centre of Excellence at NIBRT’s facility. NIBRT expects to train as many as 1,500 people annually on next-generation biologic manufacturing technologies, which will now include GE single-use technologies. Those same technologies will be used in GE BioPark Cork’s manufacturing facilities.

To read the original story, published on GE Reports, click here.

Follow us on Twitter and Facebook for updates on the latest pharmaceutical and biopharmaceutical manufacturing news!

Filed Under: Drug Discovery