Higher pressures and smaller particles combined with software and hardware improve protein purification.

Advances in column and instrument technology give researchers more tools for sample analysis. |

In 1900, Russian botanist Mikhail Tsvet performed a clever experiment. After filling a glass column with calcium carbonate, the primary ingredient in limestone, he loaded an aliquot of plant extract into the tube. As the extract flowed through the column, different pigments migrated at different rates, eventually resolving into clearly defined, colorful bands. Tsvet named the technique chromatography.

Today, chromatography remains one of the most important techniques in biology. The basic principle remains the same, but scientists and gear manufacturers have tweaked it relentlessly.

“One term we use is peak capacity—that’s the amount of peaks you can stuff into the active part of the chromatograph,” says Pat Young, PhD, a product manager at Waters in Milford, Mass. Young adds that “theoretically there’s going to be a limit to the amount of peaks you can resolve, but I don’t think we’re close to reaching it in some of these complex proteomics samples.”

Like most things in protein chemistry, improving peak capacity is a hard slog, but through a combination of higher pressure columns, smaller resin particles, and innovative new software and hardware, equipment and column makers are researchers are gradually making progress.

Feeling the pressure

The most obvious change in chromatography in recent years has been the rise of high pressure liquid chromatography (HPLC), which has become the primary preparation system for mass spectrometry. Chromatography resolution and speed go up as resin particle size and column diameter go down. With resin beads a few microns across and pressures in the thousands of pounds per square inch, HPLC systems can separate hundreds of proteins in a few minutes.

In 2004, Waters carried this a step further by introducing resins smaller than 2 µ, a format the company calls ultra performance, or UPLC. It was a major engineering accomplishment. “When you get down to a particle smaller than three microns, the amount of pressure that builds up in the column … gets above 10,000 psi,” says Michael Early, director of marketing in discovery sciences at Grace Davison in Columbia, Md.

click to enlarge |

Other manufacturers, including Grace, soon followed Waters’ lead, and now advanced proteomics labs are lining up to buy HPLC systems that operate at or near 15,000 psi. That’s about the pressure at the bottom of the Mariana Trench, the deepest point in the world’s oceans. HPLC experts disagree on whether even higher pressures are practical, but most companies seem to be placing multiple bets. “I see us going to smaller particles for better resolution, but I also see us branching out into other types of chemistries,” says Waters’ Young.

Rock on

Besides smaller particles and higher pressures, researchers have also tried increasing peak capacity with a completely different approach: monolithic columns. As the name implies, these columns consist of a single rod of material, usually either silicon or an organic polymer. Pores engineered into the monolith allow fluid to pass through, retaining different molecules with different affinities.

“[Monoliths have] a macroporous-mesoporous structure that allows better fluid transfer through the phase, which allows for higher efficiency separations with lower back pressures,” says Michael McGinley, bioseparations product manager at Phenomenex in Torrance, Calif. For proteomics research, Phenomenex recently introduced a nanocapillary system that uses a silicon monolith inside a tube 100 microns in diameter.

Because monolithic columns run at relatively low pressures, researchers can often plug them into existing systems without having to buy new ultra-pressure equipment. Monolithic column chemistries are also relatively easy for manufacturers to modify, and run times can be very short.

Nonetheless, even those who make monolithic columns concede that they are not a panacea. “The capacity of a monolith cannot be as high as a particulate residue can be; you get speed, but you don’t get capacity,” says Dietrich Hauffe, PhD, vice president of marketing at Dionex in Sunnyvale, Calif. Besides polymer-based monolithic columns, Dionex sells a modular set of HPLC system components for both conventional and monolithic resins.

|

Others are more pessimistic about monoliths. “Two years ago, three years ago, monolithics were all the rage,” says Grace’s Early, but he contends that the technology still has not been put into practical formats for proteomic studies. Early says that making monoliths sufficiently robust and reproducible would require manufacturing narrower, shorter columns than the ones that are currently on the market: “We didn’t see any commercially viable monoliths in the smaller sizes, where I think they would really have been applicable.”

The controversy over the future of monoliths may simply reflect a transatlantic divide. According to Hauffe, European proteomics centers are increasingly experimenting with a completely different strategy from the short columns and high pressures their American counterparts favor. “With monoliths, for instance, you have less backpressure, and it’s much easier to go into a one meter length column,” says Hauffe. Ultra-long columns and low pressures yield impressive resolution, but they can take two hours for each run, so the approach is not suitable for everyone.

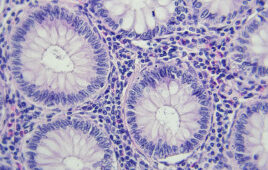

click to enlarge |

Cleaning up and hooking up

Regardless of the type of HPLC system they use, most researchers can improve their peak capacity and reproducibility by optimizing some of the peripheral steps in the purification. “You might have been able to get away with less-than-pristine mobile phase purity with conventional HPLC, but column blockage is a big issue with UPLC now,” says Early. Besides preparing fresh mobile phase reagents daily, he recommends using guard columns or other pre-treatment strategies to trap impurities before they get to the UPLC or HPLC stage of the system.

Running the experiment and analyzing the torrent of data afterward also requires careful thought. To help integrate this process, many researchers now turn to the popular Chromeleon software package from Dionex. By working with major HPLC and mass spectrometry equipment makers, the company has built a single interface that can control disparate components from different vendors.

With modern systems now able to resolve sizable chunks of the proteome in a matter of minutes, it would be easy to conclude that HPLC technology is reaching its practical limits. But those working on the next generation of methods are more optimistic. “I fall into the camp that we’re not at the end, we’re just one breakthrough away from the next step,” says Early.

About the Author

Originally trained as a microbiologist, Alan Dove has been writing about science and its interfaces with industry and government for more than a decade.

This article was published in Drug Discovery & Development magazine: Vol. 11, No. 5, May, 2008, pp. 45-47.

Filed Under: Genomics/Proteomics