Web Exclusive

Trangenic technology is successfully used to develop goats to produce prophylaxis for nerve gas victims.

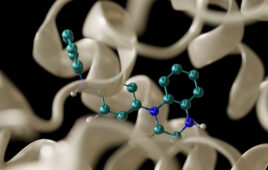

Butyrylcholinesterase (BChE) has been studied for decades as a prophylaxis for the exposure to organophosphorous (OP) nerve agents such as VX, sarin, and soman gas. Although it is widely accepted that BChE has great potential to protect both the war-fighter and civilians against OP exposure, the concentration of BChE in plasma (2 mg/L) makes large-scale purification and commercialization improbable. Standard recombinant expression systems that have traditionally been successful in the production of biologic drugs (Escherichia coli, Pichia, CHO cells) have been explored but with disappointing results. These attempts proved to be inefficient and either failed to produce viable yields or, if high yields were attained, the BChE was not enzymatically-active.¹ While it is disappointing that standard techniques have failed, PharmAthene took an alternative approach to successfully solve this expression problem using transgenic technology and successfully developed an advanced development program for the recombinant BChE drug Protexia. The basic process of producing a transgenic expression platform for the production of recombinant BChE (rBChE) is:

1. Construction of the transgene

2. Founder generation by pronuclear microinjection

3. Founder characterization for transgene and gene expression

4. Selected founder multiplied by SCNT and prepubertal LOPU-IVEP

5. Scale-up by artificial insemination

6. Protexia production herd

Construction of the transgene

A mammary gland-specific transgene was constructed by inserting a human BChE cDNA construct downstream of the caprine (goat) beta casein gene to target expression in the mammary glands of lactating females.2 The BChE transgene consists of chicken beta-globin insulator sequences and 5’ and 3’ portions of the goat beta-casein (BCN) gene, which are separated by the BChE cDNA clone. The chicken insulator fragment is comprised of tandem copies of the 1.2-kb insulator sequence, which acts to protect the transgene and its promoter from exogenous signals from the surrounding genome that might silence expression. The 6.7-kb 5’ portion of the beta-casein gene is used to target the expression of the transgene to the mammary gland and regulate the secretion of rBChE into the milk. The BChE plasmid was generated through a step-wise cloning process starting with a PharmAthene-proprietary cloning vector.

Generation of founder animals

Once the BChE transgene was constructed, a founder animal was generated to form the genetic base of the transgenic herd. This founder animal was then sequentially multiplied to form the production herd. Goats of conventional dairy breeds (mainly Saanen) were used as oocyte donors, while other available breeds served as recipients during the founder generation program. A linear transgene cDNA fragment was prepared and transferred to embryos by DNA pronuclear microinjection, a process by which harvested goat embryos are injected with a microscopic needle containing the cDNA sequence. The injected embryos were then cultured in vitro to produce viable zygotes, which were then transferred into the oviducts of estrus-synchronized recipient goats by means of a mid-ventral laparotomy under general anaesthesia.

Characterization of founder animals

Six F0 generation goats, one male and five females, were found to be transgene-positive by PCR screening. Further, Southern blot and fluorescence in situ hybridization (FISH) analyses revealed that the six transgenic goats carried a variety of intact transgene copies inserted randomly in their respective genomes. The transgene integrated in tandem head-to-tail or head-to-head arrays, as confirmed by Southern blot using different restriction enzyme digestion combinations. Obviously, insertion of a transgene is only relevant if the protein of interest is properly expressed. Therefore, the next step was to induce expression via the beta casein promoter by stimulation of the mammary glands followed by an assessment of protein expression and functionality using a cholinesterase activity assay. The five female transgenic goats were induced to lactate by the administration of a hormonal therapy consisting of mammogenic stimulation based on estradiol and progesterone for two weeks, followed by a lactogenic stimulation based on glucocorticoids for three days in order to stimulate lactation. Milk was then collected and characterized for rBChE expression levels by Western blot and cholinesterase activity. A single goat was selected for production of subsequent generations based on the results of all characterization testing (transgene copy number, integration sites, and high rBChE expression level), as well as the viability of her transgenic line.

Transgenic founder multiplication

The selected founder animal was cloned at PharmAthene using Somatic Cell Nuclear Transfer (SCNT) technique. Through the use of SCNT, a “mini-herd” of cloned goats was generated that allowed for the production of sufficient amounts of milk to support initial proof-of-concept research and production of an F1 male for further herd amplification. A cumulus-granulosa cell line was established from cells recovered from the selected founder by follicular aspiration under laparoscopy. This cell line was then utilized for the production of reconstructed embryos by SCNT using enucleated in vitro matured oocytes as cytoplasts. Reconstructed embryos were electrically-fused, chemically-activated, cultured overnight to allow initial cleaving as a sign of development and transferred into the oviduct of estrus-synchronized recipient goats by means of mid-ventral laparotomy. A total of eight cloned goats were produced as part of this program. When genetically-characterized by PCR, Southern blot and FISH analyses, all of the clones of founder were transgenic.

Herd scale-up

To facilitate the process of generating a large production herd, advanced assisted reproduction technologies were used for the production of transgenic males from the selected transgenic founder line. Generation of transgenic males was the preferred means of scale up because males can be propagated quickly through artificial insemination of multiple females. Furthermore, both the United States Department of Agriculture (USDA) and Canada’s Scrapie Certification Program allow the use of semen coming from lesser status herds into scrapie-free herds, without losing the scrapie-free status of the herd. The founder clones were subjected to a program aimed at the in vitro production of embryos from oocytes collected by laparoscopic ovum pick-up (LOPU) at pre-pubertal ages. While pre-pubertal animals cannot become pregnant, large numbers of oocytes with good developmental capacity can be collected by laparoscopy following hormonal stimulation. Utilizing this technique allowed for the accelerated propagation of F0 clones, increasing the probability of successfully generating an F1 male. As soon as semen from the F1 male became available, it was utilized in the insemination of scrapie-free dairy goats of New Zealand origin to generate the rBChE Production Herd.

In subsequent efforts to increase the Production Herd size, new transgenic females have been generated using a combination of methods to maximize the herd expansion efficiency. These methods include the insemination of conventional females with semen from qualified transgenic males (F2, F3), the insemination of qualified transgenic females with semen from qualified conventional males and the implantation of in vitro produced embryos where one of the parents is a qualified transgenic individual and the other is a conventional animal.

Once a transgenic herd is established, the milk is no different than a fermentation broth from standard expression systems and can be processed using standard biotechnology techniques to clarify the milk and then purify the BChE for preclinical and clinical studies. Using the transgenic expression system, PharmAthene has successfully developed a recombinant product to an advanced stage of development where other expression systems have failed. This production platform has matured to the point where multiple GMP lots of clinical grade drug have been produced and the Protexia program is now in a Phase 1 clinical trial to assess its safety in humans.

References

1. D. M. Cerasoli, E. M. Griffiths, B. P. Doctor, A. Saxena, J. M. Fedorko, N. H. Greg, Q. S. Yu, Y. Huang, H. Wilgus, C. N. Karatzas, I. Koplovitz, D. E. Lenz. In Vitro and in Vivo Characterization of Recombinant Human Butyrylcholinesterase (Protexia) as a Potential nerve Agent Bioscavenger. Chemico-Biological Interactions. 2005:157-158:353-434.

2. Yue-Jin Huang, Yue Huang, Hernan Baldassarre, Bin Wang, Anthoula Lazaris, Martin Leduc, Annie Bilodeau, Annie Bellemare, Melanie Cote, Peter Herskovits, Madjid Touati, Carl Turcotte, Duncan Hockley, Douglas Cerasoli, David Lenz and Solomon Langermann. Recombinant Human Butyrylcholinesterase From Milk of Transgenic Animals to Protect Against Organophosphate Poisoning. PNAS. August 21, 2007:104;34:13603-13608.

About the Authors

Baldassarre’s expertise is assisted reproduction in ruminants and is credited with the production of the first transgenic livestock in Canada, world’s first cloned goat using in vitro transfection and SCNT transfer and world’s first offspring from prepubertal live goats.

Troyer is responsible for development activities for all of the nerve agent programs at PharmAthene. He has broad experience in the development and licensure of biologic drugs in the biotechnology industry including manufacturing, regulatory affairs and program management.

Filed Under: Genomics/Proteomics